Presentation

Exclusive distributor for Italy of precision tools, measuring instruments and chucks

Uvat is specialized in the import and distribution throughout the Italian of precision tools, measuring instruments (micrometers, indicators, gauges, bore gauges etc.) and accessories for machine tools such as mandrels and callipers. The sales network covers the whole of the organization nationally, through agents, distributors and depots that guarantee a widespread service, as well as ongoing assistance and timely supplies.

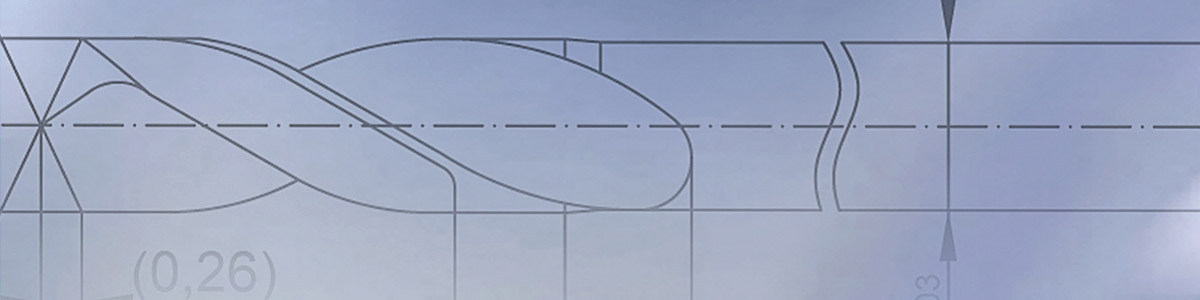

The business focuses solely on high quality products with the highest technical content. Whether referring to carbide or HSS drill bits, blade-plate or multi-cutting micro-adjustable reamers, deburring tools, chamfering tools, backspot facing tools or inserts in PCD (Polycrystalline Diamond), micrometers, indicators or mandrels , the business imperative is always the highest quality.

The world of precision mechanic workshops, where chip removal is carried out with passion every day, are our primary customers. Whether small or large, we are at their side to support them in day-to-day activities of boring, drilling, deburring, chamfering, backspot facing, milling, tapping or threading and subsequent measurement and dimensional control, wherever the need for the highest quality is always on top.

In addition to providing a wide range of products, Uvat provides its customers with continuous before and after sales service which make it a 360° privileged partner. All this, combined with the extensive know-how, allow it to be the right choice for most precision chip removal machining.

Design, production, modification and re-sharpening of tools is always carried out in a very short time, well aware of modern needs and with “just in time” tool service. The need to reduce costs at all levels of the company requires, even in the context of procurement of tools, measuring instruments and all the auxiliary material used by a modern precision mechanical workshop, constant cost reduction and optimization. Often this need translates into a drastic reduction in inventories and tools present in the “tool-room”. A service of providing new tools or sharpening in a timely manner is therefore absolutely essential.

Also thanks to the acquisition of Utensileria Noto, a company specializing in wholesale and retail of mechanical tools and machine tools, Uvat can count on 2,500 sqm warehouse and over 300,000 items in stock.

Customers are supported and advised in all phases of design and production, and tools are supplied with the “money back” guarantee, with payment only when the result is achieved. The cycle, as mentioned, ends with a rapid and complete sharpening and recovery of tools with the security of restoring productivity with regenerated tools that is comparable to that of new tools.

The latest technologies applied to precision mechanics are always proposing new products and new machinery, especially in the field of precision tools and numeric control. Daily technical progress confronts us with new opportunities and at the same time great risks and unknown events. It is here that Uvat, thanks to over forty years of experience in the industry, will recommend customers the most suitable product for individual production requirements.

Uvat’s professionalism may however be exercised only on new projects where, side by side with the customer, our technicians have the opportunity to study, drawings in hand, the best technical solutions to start production of a mechanical component. Turnkey tolling solutions with which we accompany the customer from the initial sketches to the finished product.

Uvat is therefore a privileged point of reference for all mechanical companies, from small workshops to big manufacturers of components for aeronautics or “automotive”, that wish to improve their production processes, reduce costs/piece and increase productivity. All this through a complimentary analysis of current processes and technical consultancy on improvements applicable through the use of the latest technologies in the field of precision chip removal mechanical tooling.

Uvat can provide tools that are specially designed or catalogue standard that can meet any production requirement.

KEY ELEMENTS OF OUR COMPANY

- High-quality standard and special chip removal tools

- Swiss-made Measuring & Control dimensional instruments

- Accessories for machine tools and precision chucks

- Utmost attention to quality and ongoing technical assistance

- 40 years of experience in precision tooling

- Reliable and timely re-sharpening service

- Selected products worldwide for their quality

- Specialists in boring, drilling, milling and tapping

Italiano

Italiano  English

English